How Pentanes revolutionise thermal insulation

Energy efficiency and thermal insulation have become an integral part of our everyday thoughts and decisions. Whether we are re-insulating a building, insulating pipes or buying refrigerators, we are considering savings on our energy costs and thus reducing CO2 emissions. Manufacturers of insulation for the building or refrigerator industry have recognised their responsibility and are doing their part to protect the climate. However, high-quality raw materials - such as Pentanes, without which good insulation is not possible at all - are crucial for optimal insulation performance.

Haltermann Carless – a strong partner for silicone sealant manufacturers

Silicone sealants are important materials for professionals and craftsmen in the building industry. There is hardly a joint or crevice that is not filled with silicone sealant. The typical quality features are high - tear-resistant, water-repellency and colour-fast. An important contribution to this is made by the low-viscosity base oils used for this purpose, more precisely the Pilot® extender oils from Haltermann Carless. We spoke with Jan Boerrigter, Commercial Manager for Middle Distillates, and asked him how Haltermann Carless provides technical advice to manufacturers of silicone seals in the development of formulations, the new hydrogenation plant and individual supply chain concepts.

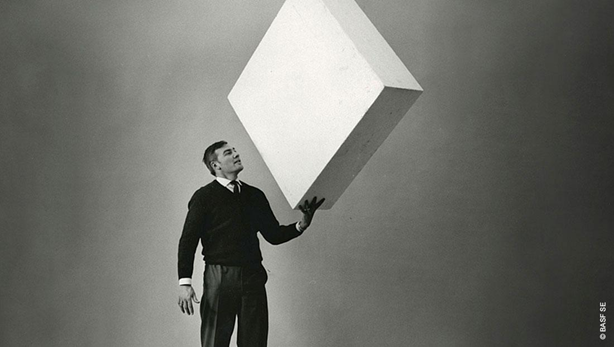

70th Anniversary of Styropor® – Haltermann Carless congratulates BASF

An anniversary like this is not celebrated every year. While many plastics influence our lives on a daily basis, only very few manage to become truly iconic. Polystyrene in its foamed form, Styropor®, has accomplished this. 70 years ago, the first patent on foamed Polystyrene was granted. The brand name Styropor® became immortal and Styropor® became a synonym for a whole class of products. Haltermann Carless would like to congratulate BASF on this very special anniversary!

Which Pentanes are suitable for the production of insulating materials?

Polyurethane or polystyrene insulation boards can be foamed using various processes. Which process is used is primarily a matter of ecological and economic considerations. Pentanes are the foaming agent of choice. Their high performance and sustainability are particularly convincing. In this blog article, find out which products are currently used in the insulation industry and what increasing role Pentanes are playing in the production of insulation materials.

Haltermann Carless Pentane: Tailor-made and ecologically beneficial

The insulation industry plays a crucial role in energy transition. More efficient insulation for refrigerators and freezers or even pipe insulation contribute to achieving our climate goals. Particular emphasis, however, is placed on building insulation. Improving energy efficiency in buildings is therefore crucial in achieving the ambitious goal of carbon-neutrality by 2050, set out in the European Green Deal. Find out here why this will only work with high-quality Pentanes and reliable suppliers.

Where is Pentane used? Overview of the different applications

Pentanes are mainly known as blowing agents for insulation materials. But they can do even more: the three isomers n-Pentane, iso-Pentane and Cyclopentane can each show their advantages in a wide variety of applications, either on their own or as a blend. In this article you can read about the differences between the three Pentane isomers and the applications in which they have proven to be particularly useful.

From styrene to polystyrene to the production of Styropor®

Polystyrene is a plastic polymer that is used in many areas of everyday life: be it for yogurt containers, packaging materials, toy bricks or for insulation purposes in building and construction. Probably the best-known use, however, is foamed polystyrene, also known as Styropor®. We have taken a closer look at this special material and answer questions about the production, properties, use and recycling of polystyrene in this article.

PU foam and PIR foam – production, use and recycling

The processing of polyurethane into a foam opens up various possible applications. As an all-rounder for sealing, bonding and insulating, PU is mainly used in the construction industry. The food industry also benefits from the good thermal and cooling insulation properties. In this article, you will learn all about the production of PU and PIR foam, the areas of application and how they are to be considered from an ecological point of view.

Polyurethane and Polyisocyanurate – a versatile plastic

Polyurethane surrounds us in almost all areas of life. Whether in shoes, surfboards or as a high-performance insulating material, polyurethane's versatility allows it to be used in a wide variety of forms and functions. In this article, learn what polyurethane is, how it is manufactured and how its properties can be adapted to individual needs.

Latest Blog Posts

Topics

- Aerospace (7)

- Agrochemicals (7)

- Aromatic Solvents (8)

- Automotive Industry (4)

- Base Oil (3)

- Construction (19)

- Digitalisation (3)

- Extender Oil (3)

- Food Industry (3)

- Fuels (6)

- Insulation (17)

- Middle Distillates (16)

- Paints, Coatings & Adhesives (5)

- Pentanes (29)

- Pharmaceutical Industry (11)

- Racing Fuels (2)

- Refrigerator Industry and Cooling Logistics (4)

- Silicone Sealants (1)

- Sites & Production (7)

- Solvents (16)

- Supply Chain (11)

- Sustainability (31)

- Sustainable Aviation Fuel (SAF) (9)

- Water Treatment (3)