/airplane-kid_iStock-493338162_copyright-deklofenak_2500x500px_220222_b.jpg?width=300&name=airplane-kid_iStock-493338162_copyright-deklofenak_2500x500px_220222_b.jpg)

SUSTAINABLE AVIATION FUEL (SAF)

READY TO TAKE-OFF: HALTERMANN CARLESS INVESTS IN SUSTAINABLE AVIATION FUEL

As a fuel pioneer, Haltermann Carless is committed to making a contribution to sustainable mobility in aviation. Our ambition is to become the first commercial producer of Sustainable Aviation Fuel in Germany. The market demand for SAF is high. Because only with SAF is it possible to realise a reduction in CO2 emissions in aviation in the short term.

Sustainable Aviation Fuel (SAF) will play an important role in future sustainability plans designed to reduce CO2 emissions worldwide. The EU has included the increased use of SAF in its plans for a climate-neutral Europe by 2050. Part of these plans is the → ReFuelEU Aviation initiative. It regulates a SAF blending requirement for fuels supplied to EU airports. The plan is to gradually increase the minimum proportion of Sustainable Aviation Fuel: from 2 % in 2025 to 6 % in 2030 up to 70 % in 2050.

The demand for renewable drop-in fuels or sustainable aviation fuel is high. As an innovative chemical company, Haltermann Carless has long been focusing on sustainable hydrocarbons such as biofuels. Now we want to become the first commercial SAF manufacturer in Germany with production at our Speyer site in 2026.

"Haltermann Carless aspires to be the first commercial manufacturer of Sustainable Aviation Fuel in Germany."

"Our future SAF production illustrates our ambition to remain a steady pioneer in the field of high-quality hydrocarbons while making a tangible contribution to defossilisation and reducing greenhouse gas emissions."

OUR INVESTMENT PROJECT

SUSTAINABLE AVIATION FUEL (SAF)

OUR WAY TO PRODUCE SAF

Alcohol-to-Jet (AtJ) process

There are various technologies for the production of Sustainable Aviation Fuel (SAF). We at Haltermann Carless have opted for the Alcohol-to-Jet (AtJ) process.

This is a proven and future-proof SAF technology that allows a high degree of flexibility in terms of raw materials (2G, waste and residues in accordance with EU RED II Annex IX).

In the Alcohol-to-Jet (AtJ) process, alcohol is produced from plant-based, predominantly sugar-containing waste materials.

This alcohol is then dehydrated and converted into kerosene using standard refinery processes.

You can find more information on the Alcohol-to-Jet (AtJ) process in our blog →

FURTHER TECHNOLOGIES FOR THE PRODUCTION OF (SAF)

Renewable energy from the sun, water or wind, CO2 and water can be used to produce a synthetic gas, which in turn is used to produce liquid paraffin through synthesis and fractionation in a Fischer-Tropsch plant.

With this large-scale method, any carbon-rich material can be used. It is therefore particularly suitable for processing biomass from which paraffin can be produced.

Sunlight plays the decisive role - in a solar reactor, concentrated solar rays split a metal oxide into metal and oxygen ions. Carbon dioxide and water vapour are then added to form the synthetic gas, which is then converted into alternative paraffin using the Fischer-Tropsch process.

Hydrogenated vegetable oils or HVOs are vegetable oils that are converted into hydrocarbons by means of a catalytic reaction with the addition of hydrogen (hydrogenation). HVOs can be used as an admixture in fuels or can replace them completely.

In this process, SAF is produced on the basis of esters and fatty acids. The fats and oils, consisting for example of used fats or food waste, are first hydrogenated. The resulting oil can be refined into paraffin in a similar way to crude oil.

CONVINCE YOURSELF OF

HALTERMANN CARLESS...

- PRODUCTION SITE

- SUSTAINABILITY ENGAGEMENT

- PIONEERING SPIRIT

In 2022, Haltermann Carless commissioned a hydrogenation plant at the Speyer site in Germany, an investment project for the manufacture of sustainable products and modern technologies. As a company, we see ourselves in an excellent position for the future and can provide our customers with high-quality, state-of-the-art raw materials as they move towards greater sustainability.

Speyer is an important production site for Haltermann Carless. Continuous development and investment has been an integral part of our history for over 50 years. With around 120 employees, we manufacture a broad portfolio that meets the highest quality and sustainability standards. To achieve this, we rely on modern technologies, improved products and sustainable solutions.

In addition to manufacturing sustainable products, we also implement our sustainability standards at the plant itself, for example with electricity that comes from certified renewable sources.

→ More information on the Haltermann Carless Speyer production site

Sustainability - a big word. So is implementation. To achieve this, we continuously take one step at a time and rely on our experience, our knowledge and our team spirit. Haltermann Carless has the best prerequisites for transforming the company's own sustainability strategy into success, including:

-

Our decades of expertise in the production of biofuels.

-

A broad and constantly growing product portfolio made from renewable raw materials.

-

Our production sites in Harwich, Hamburg and Speyer with the best logistical connections to all transport infrastructures for fast, worldwide delivery.

-

Our certified, modern research and development laboratories.

-

Our modern production units such as the new hydrogenation unit.

-

The introduction of a dedicated Corporate Development & Sustainability department with sustainability specialists.

-

Our renewed EcoVadis Gold award as well as ISCC EU & ISCC PLUS certifications for our commitment to sustainability

-

Our partnership-based customer relationships help us to offer individual and sustainable solutions.

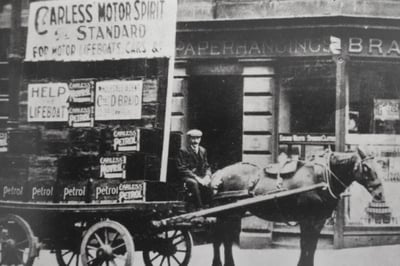

Being a pioneer is in our genes - so is inventing fuel! So it is only natural that we at Haltermann Carless want to be at the forefront of the development of sustainable aviation fuels. We are convinced that we have the best prerequisites for this:

We have been fuel experts since the 19th century

With Carless' invention of "Petrol" in 1893, we look back on a very long history of expertise in the production of fuels.

Being a pioneer is in our corporate DNA

Our founding father Haltermann refined crude tar from the Hamburg gas works and eventually became a pioneer in the development of hydrocarbon specialties. At the same time, at the end of the 19th century, the company Carless, Capel & Leonard was the leading British source of highly refined fuel.

We have experience with "green"

Our knowledge and experience is reflected in our growing sustainable product portfolio - from biobased fuels to sustainable hydrocarbons and chemicals that offer our customers sustainable alternatives and lead to a significant reduction in greenhouse gas emissions.

We are going the extra mile

We put our ideas into practice by investing in modern technologies and the latest equipment. Our new hydrogenation plant or supplying our production sites with electricity from renewable sources are just a few examples.

Sustainability is not a trend for us,

but a social responsibility and a corporate orientation - we have been following this path for a very long time. Back in the early 1990s, we were one of the first medium-sized chemical companies to introduce the principles and practices of the Responsible Care program. Since then, we have implemented sustainability step by step in all areas.

5 FACTS ABOUT SAF

Sustainable Aviation Fuel (SAF) is the generic term for all aviation fuels that are produced without the use of fossil fuels such as crude oil. They also meet sustainability criteria, for example to avoid competition with food production or the destruction of ecosystems through additional agricultural land.

Liquid fuels will continue to be indispensable for air travel in the long term. SAF is a drop-in fuel, i.e. it is a fully interchangeable replacement for fossil kerosene in aircraft and requires no changes to airport infrastructure or aircraft technology. Depending on the type of SAF, it can currently be blended with fossil kerosene in a ratio of up to 50/50.

There are several certified pathways to produce SAF for use in commercial aviation. These SAF technologies can convert a variety of feedstocks such as agricultural waste, used cooking oil, biogenic carbon and green hydrogen (power-to-liquid) into sustainable aviation fuel. Haltermann Carless relies on ATJ (Alcohol-to-Jet) technology and thus on raw materials for advanced biofuels from waste and residues. Our ATJ plant is located in Germany, SAF production site Speyer.

As SAF is based on renewable raw materials, carbon is continuously recycled instead of producing additional CO2 through fossil fuels, thus closing the carbon cycle. The new generation of SAF is mainly produced from biogenic residues, for example from waste-based biomass, and can save up to 85% CO2 compared to conventional kerosene. In the long term, SAF can enable virtually CO2-neutral air travel.

SAF is by far the biggest lever for reducing CO2 emissions in aviation (65% of the contribution from SAF alone). The implementation of the EU climate targets and mandates for the blending of SAF require considerable production volumes and thus significant investments in new production capacities:

- 5 million tons of SAF in 2030

- 40 million tons of SAF in 2050

/airplane-green_iStock-171331613_copyright_leonard_c_2500x1000px_210331.jpg?width=300&name=airplane-green_iStock-171331613_copyright_leonard_c_2500x1000px_210331.jpg)

INTERESTING FACTS ABOUT SUSTAINABLE AVIATION FUEL

- The aviation industry is responsible for 2 - 3 % of global CO2 emissions.

- The first test flight with SAF took place in 2008.

- SAF offers the potential to reduce greenhouse gas emissions by up to 80 %.

- SAF leads to a significant reduction in soot particles compared to conventional kerosene.

- Scheduled flights using alternative aviation fuel are visible on an ICAO map in real time:

Flight Tracker - Live Flight Tracking - Plane Finder

WHAT IS THE SAF FRAMEWORK?

- MARKET REQUIREMENTS

- EUROPEAN GREEN DEAL

The aviation industry has firmly anchored sustainable goals and the reduction of CO2 emissions in its objectives for many years in order to enable concepts for more climate protection. SAF is recognised as a solution that enables large greenhouse gas savings quickly.

Many solutions have already been implemented or are constantly being improved, such as lighter aircraft, turbine technology, kerosene-saving take-offs and landings or CO2-neutral airports. However, Sustainable Aviation Fuel (SAF) is currently the measure with the greatest potential for reducing Greenhouse Gas (GHG) emissions - and the one that can be implemented the fastest. Hydrogen or electric-powered aircraft are still visions of the future and cannot currently be used for commercial air traffic on medium and long-haul flights.

Advantages of Sustainable Aviation Fuel (SAF):

-

Designed as drop-in fuels, they are compatible with conventional kerosene, i.e. they can be mixed and interchanged.

-

They meet the same high quality standards and comply with all safety requirements.

-

They do not require any modifications to the aircraft, the turbines or the refueling system.

The European Green Deal is one of the most important regulatory initiatives to minimize greenhouse gases and combat climate change in the long term. Europe aims to achieve climate neutrality by 2050.

Important cornerstones for the topic of SAF are also the

-

"Fit for 55" initiative: climate target plan for 2030. The catalog of measures in reformed and new directives and regulations aims to reduce greenhouse gas emissions in the EU by 55% by 2030.

-

Classification of raw materials for the production of SAF in accordance with the Renewable Energy Directive.

-

ReFuelEU Aviation initiative: A series of initiatives aimed at increasing the supply and use of SAF. More information on the ReFuelEU initiative can be found here.

Further sustainability efforts

-

Back in 2016, the member states of the UN aviation organization ICAO adopted a global CO2 compensation system - CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation) - for air traffic in Montreal.

-

The International Air Transport Association (IATA) has also formulated ambitious sustainability targets for the aviation industry in its "Way Point 2050".

-

The SAF issue is now not only being driven forward by politicians and industry. Passengers also support the efforts and are prepared to pay a higher price for flights with reduced emissions.

HALTERMANN CARLESS BLOG

Here is a selection of our latest blog posts on the topic of SAF:

Sustainable Aviation Fuel (SAF) - solution for climate-neutral flying

READ MOREAlcohol-to-Jet (AtJ) process can help deliver sustainable flying

READ MORESAF from Haltermann Carless contributes more climate-neutral aviation

READ MORE