Harwich – a versatile production site

Harwich, UK, is one of the key production sites within the Haltermann Carless group. Here we manufacture our Caromax® aromatic solvent portfolio for Agrochemicals and Fuel Additives, and a variety of Oil & Gas products. Additionally, we blend high-performance Fuels, which are used for specific applications, such as racing or historic cars, first fill or engine development.

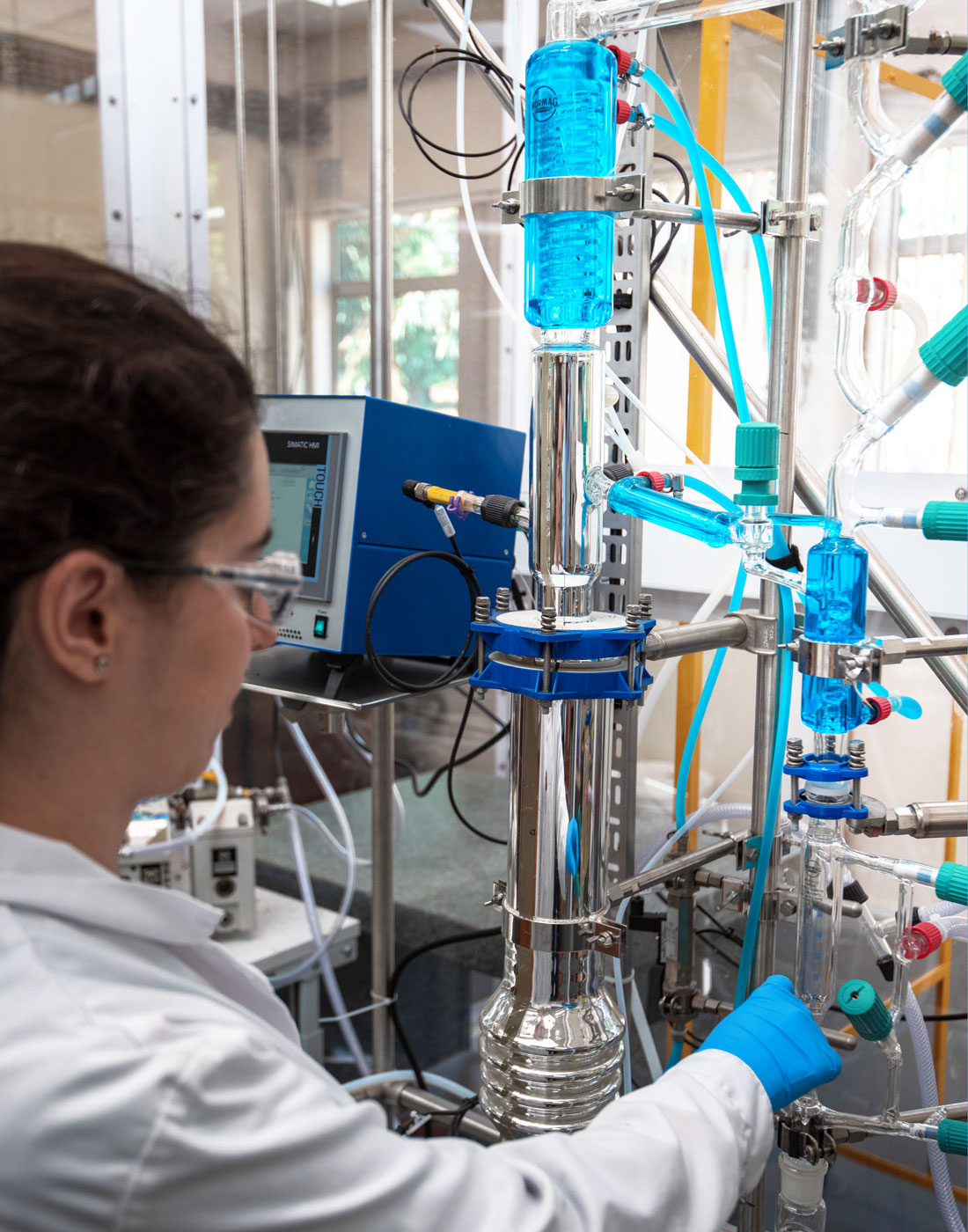

With our sophisticated distillation and blending facilities, the Harwich Manufacturing Centre is capable of producing large or small scale quantities of products to precise specifications, tailor-made to customer requirements.

Facts at a glance:

- Site foundation: 1964

- Processing Facilities: 2-batch distillation units, 3- and 4-column continuous distillation plants, high precision in-tank blending, 170 tanks, production in accordance with GMP standards

- Production Capacity: 500,000 to p.a.

- Storage capacity: 150,000m3 total in 170 storage tanks (12m3 to 15,000m3); heated storage available

- Custom Processing: Available for specific customer and supplier requirements

- Logistics: Water jetty, rail siding, road facilities

- Packaging: from 25 & 50 litre cans to 200 litre drums and 1,000 litre IBCs

- Laboratory: Extensively equipped facilities to meet industry standard tests for hydrocarbon products

- Certifications: ISO 9001 (Quality), ISO 14001 (Environment) and ISO 50001 (Energy), ISO 45001 (Occupational Health & Safety)

- Operation: 24/365

- Workforce: 100 employees, plus numerous external service providers

- Portfolio: Heavy Aromatics, Gas Condensates, Pipeline Interfaces, Middle Distillates; Mixed Hydrocarbon Streams, High-performance Fuels

Harwich

Refinery Road, Harwich

Essex, CO12 4SS

United Kingdom

Contact

Email: uk@h-c-s-group.com

Phone: +44 1372 360000